Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

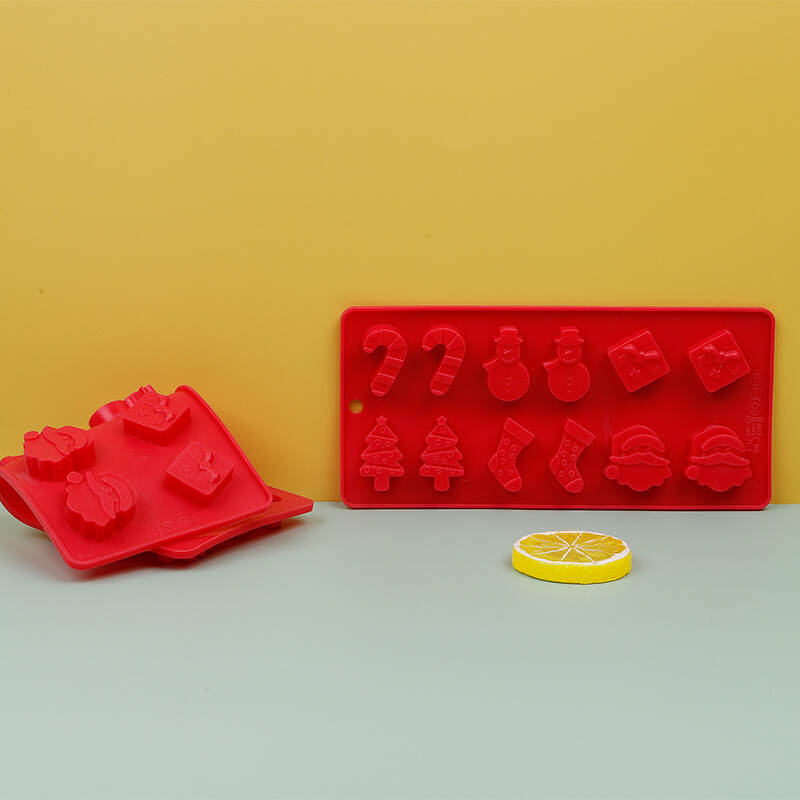

Silicone Chocolate Molds Buying Guide for Brands and Bakers

Chocolate has always been more than just a sweet treat—it is an expression of art, emotion, and creativity. In today’s baking and confectionery world, presentation matters as much as taste. That is why silicone chocolate molds have become a favorite tool for bakers, chocolatiers, and kitchenware brands. They allow professionals and home bakers alike to create chocolates in unique shapes, intricate designs, and flawless finishes with minimal effort.

For wholesalers, retailers, or brand owners, understanding how to source and select the right molds is key to meeting market demand. This guide will help you explore the advantages of silicone molds, current design trends, and how to choose the right silicone chocolate mold factory for your business.

Why Silicone Chocolate Molds Are the New Standard

Traditional chocolate molds were made from polycarbonate or metal, but silicone has quickly overtaken them for several reasons:

-

Flexibility – Silicone is soft and bendable, making it easy to release delicate chocolates without cracks.

-

Versatility – The same mold can handle chocolates, truffles, candies, or even frozen desserts.

-

Durability – High-quality silicone can withstand extreme temperatures, from ovens to freezers.

-

Ease of Use – Non-stick properties ensure quick cleaning and smooth demolding.

For commercial use, this flexibility translates into higher efficiency and less waste, while for brands, it opens up endless design possibilities.

Design Trends in Silicone Chocolate Molds

For buyers and brand owners, staying ahead of design trends is essential. Popular directions include:

-

Seasonal Themes – Valentine’s Day hearts, Christmas snowflakes, or Easter bunnies.

-

Luxury Appeal – Geometric shapes, diamond-cut patterns, or metallic-look finishes achieved with edible paints.

-

Miniature Treats – Bite-sized molds are gaining popularity in cafes and patisseries.

-

Multi-functional Molds – Shapes that can be used for chocolate, jelly, or even soaps, appealing to multi-category sellers.

Choosing a factory that offers OEM silicone chocolate molds ensures you can adapt quickly to changing trends and differentiate your brand.

What Bakers and Brands Should Look for in Silicone Chocolate Molds

1. Food-Grade Quality

Ensure that molds are made with 100% food-grade silicone—this guarantees safety and compliance for global distribution.

2. Heat and Cold Resistance

Professional bakers often use molds in both ovens and freezers. Look for molds that withstand temperatures from -40°C to 230°C.

3. Mold Thickness and Stability

Thicker molds maintain shape better during filling and cooling, especially for detailed designs.

4. Ease of Customization

Brands may want exclusive shapes to align with their identity. Factories that provide custom silicone chocolate mold design are the best partners.

5. Durability for Commercial Use

In bakeries and chocolate shops, molds are used repeatedly. Premium silicone molds last longer, reducing long-term costs.

Applications Beyond Chocolate

One of the biggest advantages of silicone molds is versatility. Beyond chocolates, they can be used for:

-

Candy Making – Hard candies, gummies, or caramel.

-

Desserts – Panna cotta, mousses, or frozen yogurt treats.

-

Savory Bites – Cheese cubes, butter shapes, or herb-infused oils.

-

Non-Food Items – Handmade soaps, wax melts, and even DIY crafts.

This multi-use potential makes silicone molds a profitable product for wholesalers and retailers, as they appeal to both baking enthusiasts and DIY hobbyists.

How to Work With a Silicone Chocolate Mold Factory

Partnering with the right silicone chocolate mold factory is crucial for scaling your product line. Here are some business factors to consider:

-

MOQ (Minimum Order Quantity) – Some factories accept small batch orders, while others focus on large-scale production.

-

Lead Time – Delivery schedules matter for seasonal launches.

-

Customization Services – Check if they can develop exclusive molds for your brand.

-

Packaging Options – Retail-ready packaging adds value for resellers.

-

Global Shipping – Experienced exporters simplify logistics for international buyers.

How Brands Can Use Silicone Chocolate Molds for Differentiation

For modern food businesses, packaging and product design are powerful marketing tools. Imagine a café selling signature chocolates shaped like its logo, or a gift brand offering holiday sets with custom-designed molds. These creative touches turn ordinary chocolates into memorable experiences.

By working closely with a capable factory, brands can develop molds that reflect their story, strengthen identity, and capture consumer attention.

Red Flags to Avoid

Not all molds are created equal. Be cautious of:

-

Strong silicone odors (a sign of poor material quality).

-

Extremely thin molds that lose shape easily.

-

Suppliers with no verifiable certification or export experience.

-

Factories that refuse to provide samples or test reports.

Conclusion

The demand for silicone chocolate molds is growing, fueled by the global baking boom and consumers’ love for unique, Instagram-worthy desserts. For brands and bakeries, choosing the right designs and partnering with a reliable silicone chocolate mold factory can unlock new opportunities and higher profits.

If you are searching for a professional supplier, SNHQUA offers both ready-to-use and customizable silicone chocolate molds, produced with 100% food-grade silicone. With experience serving global clients, we help brands and bakers expand their product lines with safe, creative, and high-quality molds.

Ready to take your chocolate creations to the next level? Contact us to explore custom mold solutions today!