Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

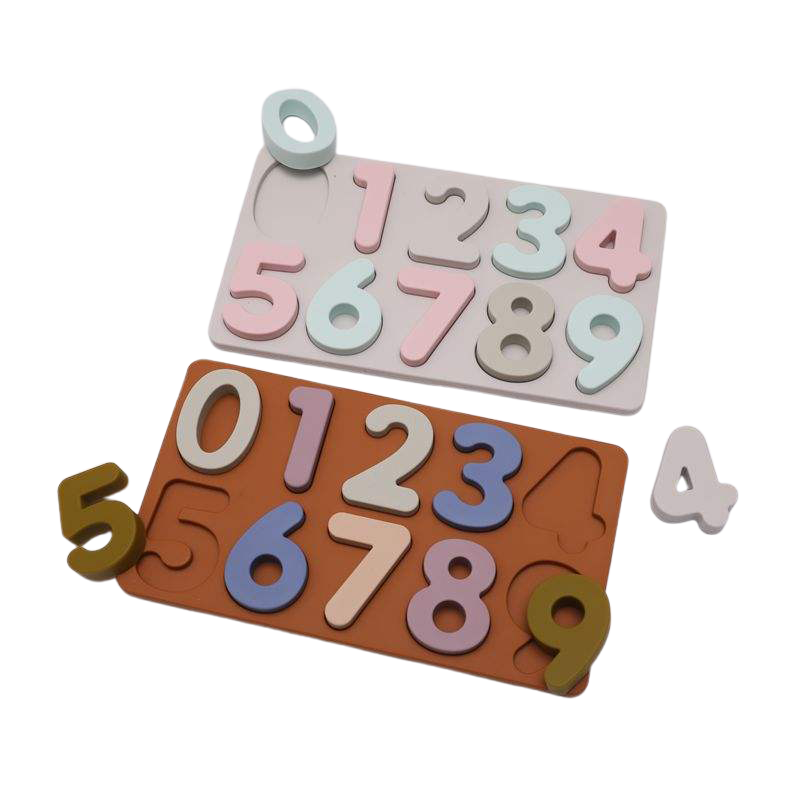

How to Find a High Quality Baby Silicone Products Factory?

When it comes to baby products, nothing matters more than safety, comfort, and reliability. Parents today are more cautious than ever, especially about items that come into direct contact with their little ones, such as pacifiers, teething toys, bottles, bowls, or feeding spoons. This is why businesses sourcing baby silicone products must be extra careful when choosing a factory. But with countless suppliers across the globe, particularly in China, how can you confidently identify a high quality baby silicone products factory?

This guide will walk you through everything you need to know—from safety standards and certifications to sourcing channels and red flags—so you can find the right partner for your brand or retail business.

Why Choosing the Right Baby Silicone Products Factory Matters

Unlike regular household goods, baby items require the highest safety standards. Poor-quality silicone can release odors, discolor easily, or even contain harmful chemicals such as BPA or phthalates. Such risks can harm not only babies but also your brand reputation.

A reliable baby silicone manufacturer ensures that:

-

All products are made with food-grade silicone.

-

Items are BPA-free, phthalate-free, and non-toxic.

-

Products meet international safety standards such as FDA, LFGB, CE, and EN71.

-

Production and packaging processes follow strict quality control systems.

Partnering with a trusted factory means you can offer parents peace of mind, knowing that every product is safe, durable, and comfortable for their children.

Key Factors to Consider When Choosing a Baby Silicone Products Factory

Finding the right partner involves more than just comparing prices. Here are the essential factors to evaluate:

1. Material Safety

The first priority is ensuring the use of 100% food-grade silicone. Ask whether the factory’s silicone materials are certified and can withstand high temperatures, boiling sterilization, and daily wear and tear.

2. Certifications and Compliance

Look for certifications that prove compliance with international standards:

-

FDA (United States)

-

LFGB (Europe, especially Germany)

-

CE Marking (European market access)

-

EN71 (toy safety standard)

A high quality baby silicone products factory will readily provide test reports from accredited labs.

3. OEM/ODM Capabilities

If you want to build your own brand, customization matters. Ask whether the factory supports OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services, such as logo printing, unique molds, or packaging design.

4. Production Capacity and Lead Time

For businesses planning long-term supply, production capacity is crucial. Check:

-

Monthly output

-

Average lead time

-

Flexibility for small or bulk orders

5. Quality Control System

High-quality factories have in-house testing equipment, sample inspections, and third-party quality audits. Request to see their process documentation.

6. Reputation and Experience

Factories with over 5–10 years of experience in silicone baby products are often more reliable. Look for client reviews, case studies, or evidence of export history to multiple countries.

Where to Find Reliable Baby Silicone Products Factories

Finding the right partner requires knowing where to look. Here are some effective ways:

Trade Fairs

Events like the Canton Fair in China or Kind + Jugend in Germany allow buyers to meet multiple suppliers in person, check samples on the spot, and build relationships.

Online B2B Platforms

Websites like Alibaba, Made-in-China, and Global Sources list thousands of factories. While convenient, always verify claims with third-party checks before placing bulk orders.

Professional Sourcing Agents

If you are unfamiliar with Chinese manufacturing, working with a sourcing agent can save time and reduce risks. They help verify factories, negotiate prices, and manage logistics.

Direct Online Search

A simple Google search like “baby silicone products factory in China” can lead to factory websites. However, always conduct due diligence before committing.

How to Verify If a Baby Silicone Factory Is High Quality

Even after finding potential suppliers, you must verify their reliability. Here’s how:

-

Request Samples

Evaluate silicone products for softness, odor, durability, and resistance to heat sterilization. -

Check Certifications

Ask for testing documents from recognized authorities such as SGS, TUV, or Intertek. -

Factory Audit

If possible, arrange an in-person visit or a third-party audit. Many factories also provide video tours. -

Trial Order

Start with a smaller batch to test production consistency, delivery time, and after-sales service.

Red Flags You Should Avoid

Not all suppliers are trustworthy. Watch out for these warning signs:

-

Factories that cannot provide authentic certification documents.

-

Prices that are suspiciously lower than market average.

-

Poor communication or reluctance to answer detailed questions.

-

No quality control process or product testing records.

-

Consistent delays in delivery schedules.

Conclusion

Finding a high quality baby silicone products factory is not only about sourcing affordable items but also about ensuring that every baby feeding set, teether, or toy meets strict safety and quality standards. By carefully checking materials, certifications, production capacity, and factory reputation, you can build a long-term partnership that benefits both your business and your customers.

If you’re currently searching for a trustworthy partner, SNHQUA is a professional baby silicone products manufacturer and supplier specializing in BPA-free, food-grade silicone items with customizable OEM/ODM options. Whether you need feeding sets, teethers, or other silicone essentials, we are committed to providing safe, innovative, and reliable solutions for global clients.

Have questions about sourcing baby silicone products? Leave a comment below or contact us—we’d love to help!